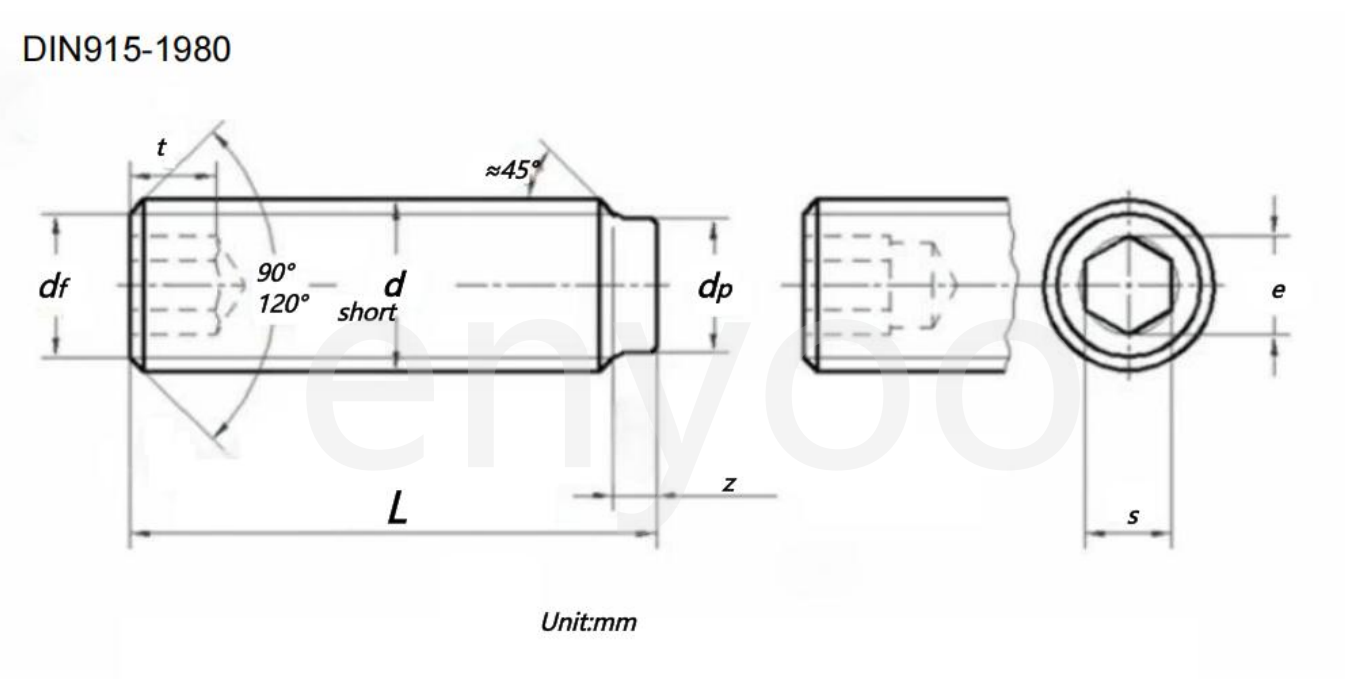

Hexagon socket set screws with Dog Point, headless, with a positive hexagonal slot, the tail of set screw is a cylinder, and must be installed with a hexagonal wrench of matching size. The hexagon socket Set Screws can into a sunken part tightly and has a flat surface.

How to use it: Put the set screw into the screw hole of the two parts which need to be fixed, and press the set screw tightly against the surface. Materials of Set Screws include carbon steel, alloy steel, stainless steel, copper, aluminum, etc. The hardness is divided into 40H 45H or 8.8, 10.9, 12.9, etc. Surface treatment of Set Screws include: natural color, black oxide, Zinc Plated, etc. The standards include German standard(DIN), American standard(AMSI) , China national standard(GB), Japanese standard(JIS). Set Screws widely used in mechanical equipment, electronic equipment, communication equipment,lighting fixture, various precision machinery, precision instruments&meters, electronic products, communication products, locks, automobiles, ships, aviation, toys and other industries, Usually used to prevent relative rotation between the bushing and the shaft.

Product features of hexagon socket set screws

Corrosion resistance ·High precision ·Strong versatility ·Not easy to rust ·Long service life

The Specification Form of DIN915 is as bellow

| DIN915 | M | ||||||||||||

| D | 1.4 | 1.6 | 1.8 | 2 | 2.5 | 3 | 4 | 5 | 6 | ||||

| P | Pitch | 0.3 | 0.35 | 0.35 | 0.4 | 0.45 | 0.5 | 0.7 | 0.8 | 1 | |||

| dp | max | 0.7 | 0.8 | 0.9 | 1 | 1.5 | 2 | 2.5 | 3.5 | 4 | |||

| min | 0.45 | 0.55 | 0.65 | 0.75 | 1.25 | 1.75 | 2.25 | 3.2 | 3.7 | ||||

| s | Nominal Size | 0.7 | 0.7 | 0.7 | 0.9 | 1.3 | 1.5 | 2 | 2.5 | 3 | |||

| max | 0.724 | 0.724 | 0.724 | 0.902 | 1.295 | 1.545 | 2.045 | 2.56 | 3.06 | ||||

| min | 0.711 | 0.711 | 0.711 | 0.889 | 1.27 | 1.52 | 2.02 | 2.52 | 3.02 | ||||

| t | min | short | 0.6 | 0.7 | 0.8 | 0.8 | 1.2 | 1.2 | 1.5 | 2 | 2 | ||

| long | 1.4 | 1.5 | 1.6 | 1.7 | 2 | 2 | 2.5 | 3 | 3.5 | ||||

| z | short | max | 0.65 | 0.65 | 0.65 | 0.75 | 0.88 | 1 | 1.25 | 1.5 | 1.75 | ||

| min | 0.4 | 0.4 | 0.5 | 0.5 | 0.63 | 0.75 | 1 | 1.25 | 1.5 | ||||

| long | max | 1.05 | 1.05 | 1.25 | 1.25 | 1.5 | 1.75 | 2.25 | 2.75 | 3.25 | |||

| min | 0.8 | 0.8 | 1 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | ||||

| e | min | 0.803 | 0.803 | 0.803 | 1.003 | 1.427 | 1.73 | 2.3 | 2.87 | 3.44 | |||

| L0 ② | Nominal Size | 2 | 2.5 | 3 | 3 | 4 | 5 | 6 | 6 | 8 | |||

| DIN915 | M | ||||||||||||

| D | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 | ||||

| P | Pitch | 1.25 | 1.5 | 1.75 | 2 | 2 | 2.5 | 2.5 | 2.5 | 3 | |||

| dp | max | 5.5 | 7 | 8.5 | 10 | 12 | 13 | 15 | 17 | 18 | |||

| min | 5.2 | 6.64 | 8.14 | 9.64 | 11.57 | 12.57 | 14.57 | 16.57 | 17.57 | ||||

| s | Nominal Size | 4 | 5 | 6 | 6 | 8 | 10 | 10 | 12 | 12 | |||

| max | 4.095 | 5.095 | 6.095 | 6.095 | 8.115 | 10.115 | 10.115 | 12.142 | 12.142 | ||||

| min | 4.02 | 5.02 | 6.02 | 6.02 | 8.025 | 10.025 | 10.025 | 12.032 | 12.032 | ||||

| t | min | short | 3 | 4 | 4.8 | 5.6 | 6.4 | 7.2 | 8 | 9 | 10 | ||

| long | 5 | 6 | 8 | 9 | 10 | 11 | 12 | 13.5 | 15 | ||||

| z | short | max | 2.25 | 2.75 | 3.25 | 3.8 | 4.3 | 4.8 | 5.3 | 5.8 | 6.3 | ||

| min | 2 | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 | 5.5 | 6 | ||||

| long | max | 4.3 | 5.3 | 6.3 | 7.36 | 8.36 | 9.86 | 10.36 | 11.43 | 12.43 | |||

| min | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | ||||

| e | min | 4.58 | 5.72 | 6.86 | 6.86 | 9.15 | 11.43 | 11.43 | 13.72 | 13.72 | |||

| L0 ② | Nominal Size | 10 | 12 | 16 | 20 | 20 | 25 | 25 | 30 | 30 | |||

| ①,df ≈ Minor thread diameter | |||||||||||||

| ②,When L ≤ L0, it is a short screw; When L>L0, it is a long screw. |

Product standard of this physical picture: DIN915

Specification: M5-0.8*35 Strength grade: 45H

Material: 40Cr Surface treatment: heat treatment, black Oxide

We are a professional Fastener manufacturer with a history of more than 20 years. Due to the large variety of screws, if you have other categories of standard parts and non-standard parts inquiries, please email us directly or contact us online. Looking forward to your contact.

Reviews

There are no reviews yet.