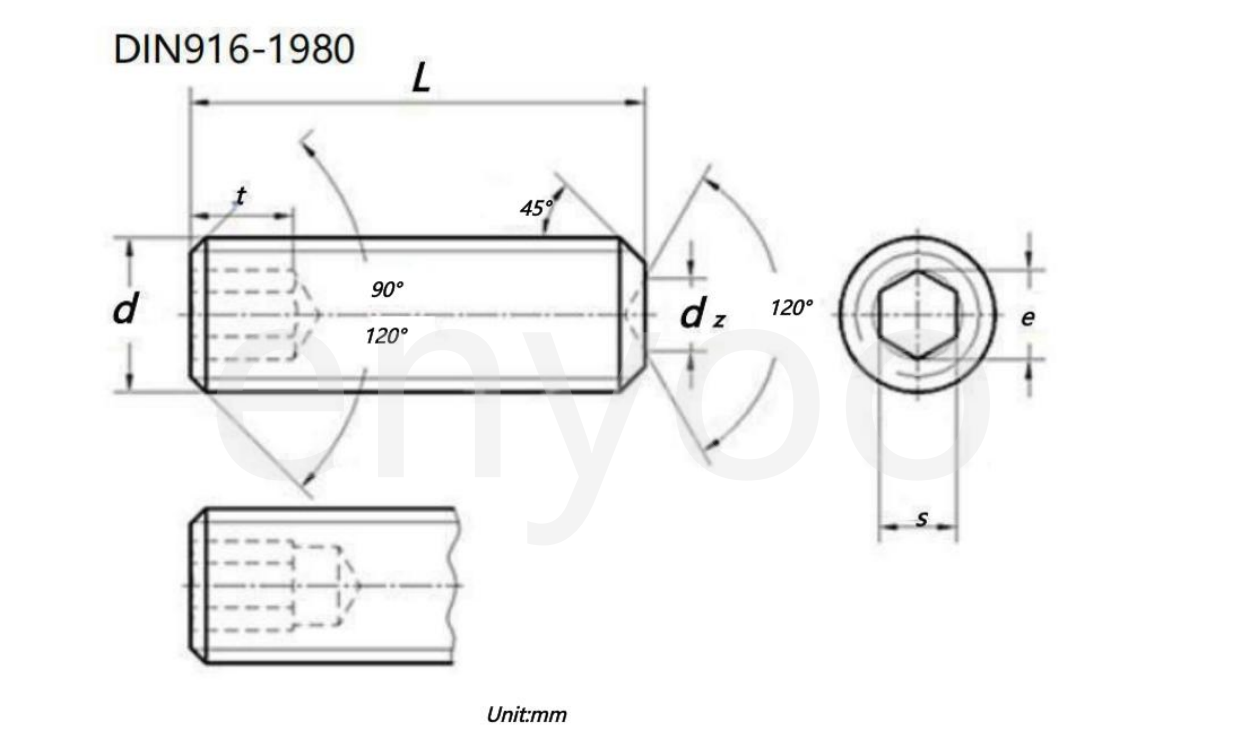

The hexagonal set screw has no head, a positive hexagonal slot, and a concave end at the end of the screw. It needs to be installed with a hexagonal wrench that matches the size. It can be used when space is limited. Because they have no head, set screws are often used in situations where the screw head does not need to be exposed, making tightening or removal easier.

Materials include carbon steel, alloy steel, stainless steel, copper, aluminum, etc. Set screws can have a range of hardness levels, depending on the material and property class

Hardened alloy steel: The most common material for set screws, with a Rockwell hardness of C45-53.

Stainless steel: Grades 18-8/303 and Metric A2 are commonly available.

17-4 PH stainless steel: A precipitation hardened stainless steel that can maintain its mechanical properties up to 600°F.

DIN 916 set screws: Property class 45H has a hardness of 45-53 HRC.

SNCM240: High-strength hexagon socket set screws that can achieve a hardness of HRC50-53.

The design of the DIN916 concave end allows the screw to concentrate the force when tightening, rather than spreading the force like a flat-end set screw. This helps create some grip within the material, providing a better hold. Application fields: automobiles and automotive new energy, military aerospace, shipbuilding industry, medical equipment, food machinery, electronic communication equipment, wind power generation, environmental protection equipment, agricultural machinery, etc.

Approximate standards GB/T80-2000, ISO4029-2003

The Specification Form of DIN916 is as bellow

| DIN916 | M | ||||||||||||

| D | 1.4 | 1.6 | 1.8 | 2 | 2.5 | 3 | 4 | 5 | 6 | ||||

| P | Pitch | 0.3 | 0.35 | 0.35 | 0.4 | 0.45 | 0.5 | 0.7 | 0.8 | 1 | |||

| dz | max | 0.7 | 0.8 | 0.9 | 1 | 1.2 | 1.4 | 2 | 2.5 | 3 | |||

| min | 0.45 | 0.55 | 0.65 | 0.75 | 0.95 | 1.15 | 1.75 | 2.25 | 2.75 | ||||

| s | Nominal Size | 0.7 | 0.7 | 0.7 | 0.9 | 1.3 | 1.5 | 2 | 2.5 | 3 | |||

| max | 0.724 | 0.724 | 0.724 | 0.902 | 1.295 | 1.545 | 2.045 | 2.56 | 3.08 | ||||

| min | 0.711 | 0.711 | 0.711 | 0.889 | 1.27 | 1.52 | 2.02 | 2.52 | 3.02 | ||||

| t | min | short | 0.6 | 0.7 | 0.8 | 0.8 | 1.2 | 1.2 | 1.5 | 2 | 2 | ||

| long | 1.4 | 1.5 | 1.6 | 1.7 | 2 | 2 | 2.5 | 3 | 3.5 | ||||

| e | min | 0.803 | 0.803 | 0.803 | 1.003 | 1.427 | 1.73 | 2.3 | 2.87 | 3.44 | |||

| L0 ① | Nominal Size | 2 | 2 | 2.5 | 2.5 | 3 | 4 | 5 | 5 | 6 | |||

| DIN916 | M8 | M10 | M12 | M14 | M16 | M18 | M20 | M22 | M24 | ||||

| D | |||||||||||||

| P | Pitch | 1.25 | 1.5 | 1.75 | 2 | 2 | 2.5 | 2.5 | 2.5 | 3 | |||

| dz | max | 5 | 6 | 8 | 9 | 10 | 12 | 14 | 16 | 16 | |||

| min | 4.7 | 5.7 | 7.64 | 8.64 | 9.64 | 11.57 | 13.57 | 15.57 | 15.57 | ||||

| s | Nominal Size | 4 | 5 | 6 | 6 | 8 | 10 | 10 | 12 | 12 | |||

| max | 4.095 | 5.095 | 6.095 | 6.095 | 8.115 | 10.115 | 10.115 | 12.142 | 12.142 | ||||

| min | 4.02 | 5.02 | 6.02 | 6.02 | 8.025 | 10.025 | 10.025 | 12.032 | 12.032 | ||||

| t | min | short | 3 | 4 | 4.8 | 5.6 | 6.4 | 7.2 | 8 | 9 | 10 | ||

| long | 5 | 6 | 8 | 9 | 10 | 11 | 12 | 13.5 | 15 | ||||

| e | min | 4.58 | 5.72 | 6.86 | 6.86 | 9.15 | 11.43 | 11.43 | 13.72 | 13.72 | |||

| L0 ① | Nominal Size | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 25 | |||

①,When L ≤ L0, it is a short screw; When L>L0, it is a long screw.

Product standard of this physical picture: DIN916

Specification: M2-0.4*3 Tensile Strength Grade: A2-70

Material: SS304 Surface treatment: Plain

We are a professional Fastener manufacturer with a history of more than 20 years. Due to the large variety of screws, if you have other categories of standard parts and non-standard parts inquiries, please email us directly or contact us online. Looking forward to your contact.

Reviews

There are no reviews yet.