Hexagonal nuts are one of the most common fixing tools. They are used in connecting with screws, bolts to fasten parts. Hexagonal nuts are made of stainless steel, carbon steel, iron, copper, and zinc alloys. The international standards for hexagonal nuts include national standard (GB), German standard (DIN), international standard (ISO), Japanese standard (JIS), and American standard (ASTM/ANSI).

1. Ordinary hexagon nut – it is widely used and is characterized by relatively large tightening force. The disadvantage is that there must be enough operating space during installation. You can use an adjustable wrench, an open-end wrench or a spectacle wrench during installation. The above wrenches require a large operating space.

2. Cylindrical head hexagon socket – it is the most widely used among all nuts because it has a relatively large tightening force and can be operated with an inner hexagon wrench. It is very convenient to install and is used in almost all kinds of structures. It has a beautiful and neat appearance. The disadvantage is that the tightening force is slightly lower than the outer hexagon head nuts. In addition, repeated use can easily damage the inner hexagon and make it impossible to disassemble.

3. Pan head hexagon nut- rarely used in machinery, the mechanical properties are the same as above, mostly used in furniture, the main function is to increase the contact surface with wooden materials and increase the ornamental appearance.

4. Headless hexagonal nut – it must be used in certain structures, such as jackscrew structures that require a large tightening force, or where the cylindrical head needs to be hidden.

5.Countersunk head hexagonal nut – mostly used in power machinery, its main function is the same as that of hexagonal nut.

6. Nylon Insert lock nut – a structure with a nylon rubber ring embedded inside the hexagonal nut to prevent the thread from loosening, and is used in high-power machinery.

7. Flange nut – mainly plays the role of increasing the contact surface with the workpiece. It is mostly used in pipes, fasteners and some stamping parts and castings.

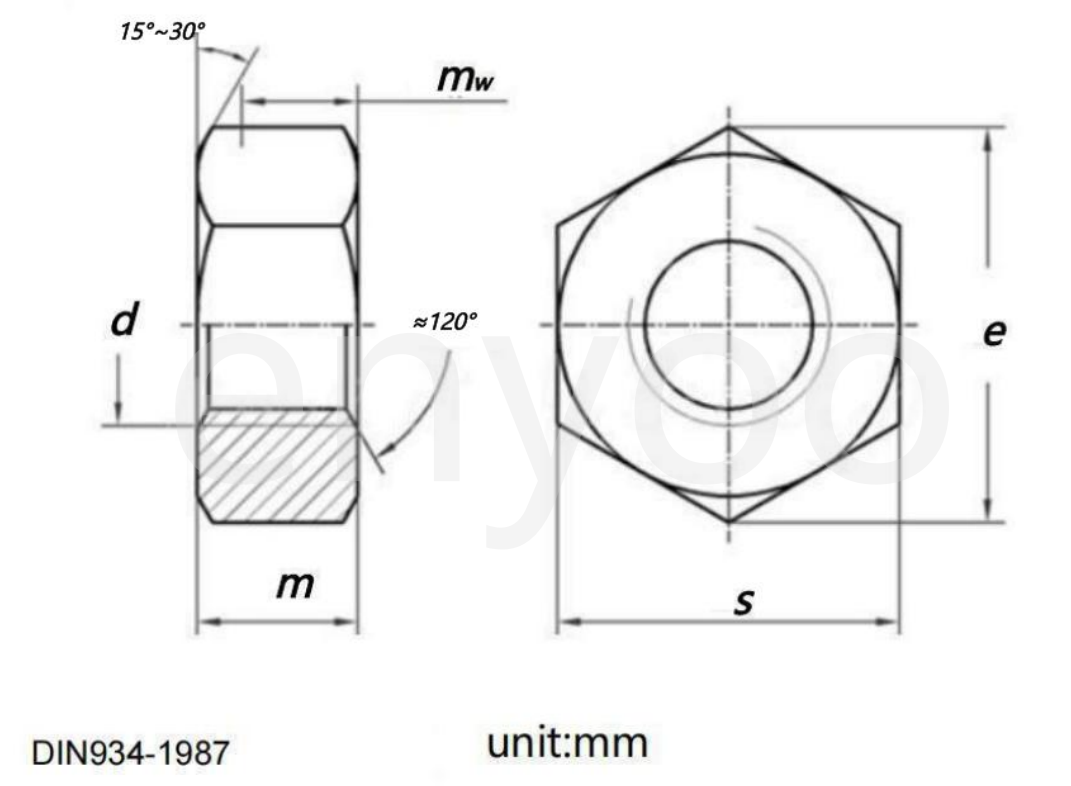

The Specification Form of DIN934 is as bellow

| DIN934 | M | |||||||||||||||||||

| D | 1 | 1.2 | 1.4 | 1.6 | 1.7 | 2 | 2.3 | 2.5 | 2.6 | 3 | 3.5 | 4 | 5 | 6 | 7 | 8 | ||||

| P | Pitch | Coarse thread | 0.25 | 0.25 | 0.3 | 0.35 | 0.35 | 0.4 | 0.45 | 0.45 | 0.45 | 0.5 | 0.6 | 0.7 | 0.8 | 1 | 1 | 1.25 | ||

| Fine thread-1 | / | / | / | / | / | / | / | / | / | / | / | / | / | / | / | 1 | ||||

| Fine thread-2 | / | / | / | / | / | / | / | / | / | / | / | / | / | / | / | |||||

| m | max=nominal size | 0.8 | 1 | 1.2 | 1.3 | 1.4 | 1.6 | 1.8 | 2 | 2 | 2.4 | 2.8 | 3.2 | 4 | 5 | 5.5 | 6.5 | |||

| min | 0.55 | 0.75 | 0.95 | 1.05 | 1.15 | 1.35 | 1.55 | 1.75 | 1.75 | 2.15 | 2.55 | 2.9 | 3.7 | 4.7 | 5.2 | 6.14 | ||||

| mw | min | 0.44 | 0.6 | 0.76 | 0.84 | 0.92 | 1.08 | 1.24 | 1.4 | 1.4 | 1.72 | 2.04 | 2.32 | 2.96 | 3.76 | 4.16 | 4.91 | |||

| s | max=nominal size | 2.5 | 3 | 3 | 3.2 | 3.5 | 4 | 4.5 | 5 | 5 | 5.5 | 6 | 7 | 8 | 10 | 11 | 13 | |||

| min | 2.4 | 2.9 | 2.9 | 3.02 | 3.38 | 3.82 | 4.32 | 4.82 | 4.82 | 5.32 | 5.82 | 6.78 | 7.78 | 9.78 | 10.73 | 12.73 | ||||

| e ① | min | 2.71 | 3.28 | 3.28 | 3.41 | 3.82 | 4.32 | 4.88 | 5.45 | 5.45 | 6.01 | 6.58 | 7.66 | 8.79 | 11.05 | 12.12 | 14.38 | |||

| per 1000 units ≈ kg | 0.03 | 0.054 | 0.063 | 0.076 | 0.1 | 0.142 | 0.2 | 0.28 | 0.72 | 0.384 | 0.514 | 0.81 | 1.23 | 2.5 | 3.12 | 5.2 | ||||

| DIN934 | M | |||||||||||||||||||

| D | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 | 27 | 30 | 33 | 36 | 39 | 42 | 45 | 48 | ||||

| P | Pitch | Coarse thread | 1.5 | 1.75 | 2 | 2 | 2.5 | 2.5 | 2.5 | 3 | 3 | 3.5 | 3.5 | 4 | 4 | 4.5 | 4.5 | 5 | ||

| Fine thread-1 | 1 | 1.5 | 1.5 | 1.5 | 1.5 | 2 | 1.5 | 2 | 2 | 2 | 2 | 3 | 3 | 3 | 3 | 3 | ||||

| Fine thread-2 | 1.25 | / | / | 2 | 1.5 | 2 | / | / | / | / | / | / | / | / | / | |||||

| m | max=nominal size | 8 | 10 | 11 | 13 | 15 | 16 | 18 | 19 | 22 | 24 | 26 | 29 | 31 | 34 | 36 | 38 | |||

| min | 7.64 | 9.64 | 10.3 | 12.3 | 14.3 | 14.9 | 16.9 | 17.7 | 20.7 | 22.7 | 24.7 | 27.4 | 29.4 | 32.4 | 34.4 | 36.4 | ||||

| mw | min | 6.11 | 7.71 | 8.24 | 9.84 | 11.44 | 11.92 | 13.52 | 14.16 | 16.56 | 18.16 | 19.76 | 21.92 | 23.52 | 25.9 | 27.5 | 29.1 | |||

| s | max=nominal size | 17 | 19 | 22 | 24 | 27 | 30 | 32 | 36 | 41 | 46 | 50 | 55 | 60 | 65 | 70 | 75 | |||

| min | 16.73 | 18.67 | 21.67 | 23.67 | 26.16 | 29.16 | 31 | 35 | 40 | 45 | 49 | 53.8 | 58.8 | 63.1 | 68.1 | 73.1 | ||||

| e ① | min | 18.9 | 21.1 | 24.49 | 26.75 | 29.56 | 32.95 | 35.03 | 39.55 | 45.2 | 50.85 | 55.37 | 60.79 | 66.44 | 71.3 | 76.95 | 82.6 | |||

| per 1000 units ≈ kg | 11.6 | 17.3 | 25 | 33.3 | 49.4 | 64.4 | 79 | 110 | 165 | 223 | 288 | 393 | 502 | 652 | 800 | 977 | ||||

| DIN934 | M | ||||||||||||||||||

| D | 52 | 56 | 60 | 64 | 68 | 72 | 76 | 80 | 85 | 90 | 100 | 110 | 125 | 140 | 160 | ||||

| P | Pitch | Coarse thread | 5 | 5.5 | 5.5 | 6 | 6 | / | / | / | / | / | / | / | / | / | / | ||

| Fine thread-1 | 3 | 4 | 4 | 4 | / | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | ||||

| Fine thread-2 | / | / | / | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | / | / | |||||

| m | max=nominal size | 42 | 45 | 48 | 51 | 54 | 58 | 61 | 64 | 68 | 72 | 80 | 88 | 100 | 112 | 128 | |||

| min | 40.4 | 43.4 | 46.4 | 49.1 | 52.1 | 56.1 | 59.1 | 62.1 | 66.1 | 70.1 | 78.1 | 85.8 | 97.8 | 109.8 | 125.5 | ||||

| mw | min | 32.3 | 34.7 | 37.1 | 39.3 | 41.7 | 44.9 | 47.3 | 49.7 | 52.9 | 56.1 | 62.5 | 68.6 | 78.2 | 87.8 | 100 | |||

| s | max=nominal size | 80 | 85 | 90 | 95 | 100 | 105 | 110 | 115 | 120 | 130 | 145 | 155 | 180 | 200 | 230 | |||

| min | 78.1 | 82.8 | 87.8 | 92.8 | 97.8 | 102.8 | 107.8 | 112.8 | 117.8 | 127.5 | 142.5 | 152.5 | 177.5 | 195.4 | 225.4 | ||||

| e ① | min | 88.25 | 93.56 | 99.21 | 104.86 | 110.51 | 116.16 | 121.81 | 127.46 | 133.11 | 144.08 | 161.02 | 172.32 | 200.57 | 220.8 | 254.7 | |||

| per 1000 units ≈ kg | 1220 | 1420 | 1690 | 1980 | 2300 | 2670 | 3040 | 3440 | 3930 | 4930 | 6820 | 8200 | 13000 | 17500 | 26500 | ||||

①In the case of sizes of M110 or more, the hexagon edges may be radiused.

②This standard has been replaced by ISO 4032, ISO 8673 and ISO 8674

③Material:

a)Steel, Property class: ≤M2.5: 6; M3~M39:6,8,10; > M39:subject to agreement. Standard DIN 267-4

b)Stainless steel, Property class: ≤M39: A2-70, A4-70; >M39: subject to agreement. Standard DIN 267-11

c)Non-ferrous metal, Property class: subject to agreement. Standard DIN 267-18

Product standard of this physical picture: DIN934

Specification:M4-0.7 Tensile Strength Grade:A2-70 Material:SS304 Surface Treatment:Plain

We are a professional Fastener manufacturer with a history of more than 20 years. Due to the large variety of screws, if you have other categories of standard parts and non-standard parts inquiries, please email us directly or contact us online. Looking forward to your contact.

Reviews

There are no reviews yet.