Cross recessed countersunk head screws are used to connect two connected parts. One of the parts is made through, and the other part is made into an internal thread hole. Cross recessed countersunk head screws are generally used in electrical equipment, electronic machinery, mechanical equipment, household appliances, digital products, water conservancy projects, decoration construction, etc.

Countersunk head screws are generally made of metal screw wire. After being formed, they are rolled into threads. They are cylindrical and have a flat head, which is like an inclined surface surrounding the side of the screw, allowing the screw to tightly lock the screw cap or other objects. . Countersunk head screws have a larger diameter at the top, which can be round or hexagonal, allowing tools such as a screwdriver or wrench to turn the screw. The more protruding top also prevents the screw from drilling too deeply through the material and increases the pressure of the screw on the material. Countersunk head screws can usually be removed or re-inserted at will without losing their efficiency. They also provide greater strength than nails and can be reused. The head of the countersunk head screw can be completely sunk in the product material used, and the screw head will not act as an obstruction.

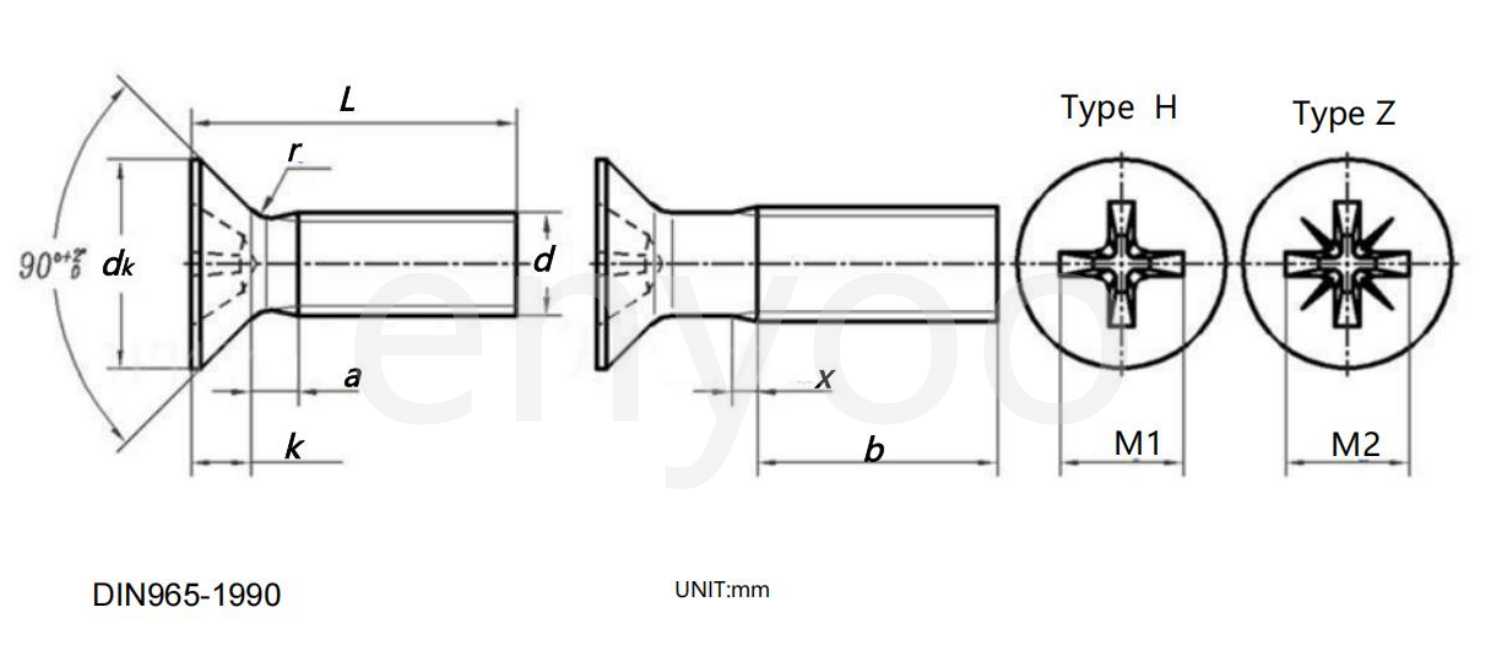

DIN965 countersunk head screws can be embedded into the surface of the workpiece without protruding, making the surface of the workpiece smoother and more beautiful, In terms of size, DIN965 is almost close to GB819

The Specification Form of DIN965 is as bellow

| DIN965 | M | |||||||||||

| D | 1.6 | 2 | 2.5 | 3 | 3.5 | 4 | 5 | 6 | 8 | 10 | ||

| P | Pitch | 0.35 | 0.4 | 0.45 | 0.5 | 0.6 | 0.7 | 0.8 | 1 | 1.25 | 1.5 | |

| a | max | 0.7 | 0.8 | 0.9 | 1 | 1.2 | 1.4 | 1.6 | 2 | 2.5 | 3 | |

| dk | max=nominal size | 3 | 3.8 | 4.7 | 5.6 | 6.5 | 7.5 | 9.2 | 11 | 14.5 | 18 | |

| min | 2.75 | 3.5 | 4.4 | 5.3 | 6.14 | 7.14 | 8.84 | 10.57 | 14.07 | 17.57 | ||

| k | max | 0.96 | 1.2 | 1.5 | 1.65 | 1.93 | 2.2 | 2.5 | 3 | 4 | 5 | |

| r | max | 0.4 | 0.5 | 0.7 | 0.8 | 0.95 | 1 | 1.3 | 1.6 | 2 | 2.5 | |

| x | max | 0.9 | 1 | 1.1 | 1.25 | 1.5 | 1.75 | 2 | 2.5 | 3.2 | 3.8 | |

| Socket No. | 0 | 1 | 1 | 2 | 2 | 2 | 3 | 4 | 4 | |||

| M1 | 1.7 | 2.35 | 2.7 | 2.9 | 3.9 | 4.4 | 4.6 | 6.6 | 8.7 | 9.6 | ||

| M2 | 1.8 | 2.2 | 2.5 | 2.8 | 3.7 | 4 | 4.4 | 6.1 | 8.5 | 9.4 | ||

①Material:

a)Steel, Strength class (material): 4.8,5.8,8.8. Standard DIN ISO 898-1

b)Stainless steel, Strength class (material): A2-70,A4-70. Standard DIN 267-11

c)Non-ferrous metal, Strength class (material): CuZn=copper zinc alloy, CU2 or CU3 according to the manufacturer’s choice . Standard DIN 267-18

d)Other strength classes or materials or a certain material, e.g. CU3, by agreement

Product standard of this physical picture: DIN965

Spec:M3-0.5*8 Strength Class:A2-70 Material:SS304 Surface treatment:Passivation+Nylon Patch Coating

We are a professional Fastener manufacturer with a history of more than 20 years. Due to the large variety of screws, if you have other categories of standard parts and non-standard parts inquiries, please email us directly or contact us online. Looking forward to your contact.

Reviews

There are no reviews yet.