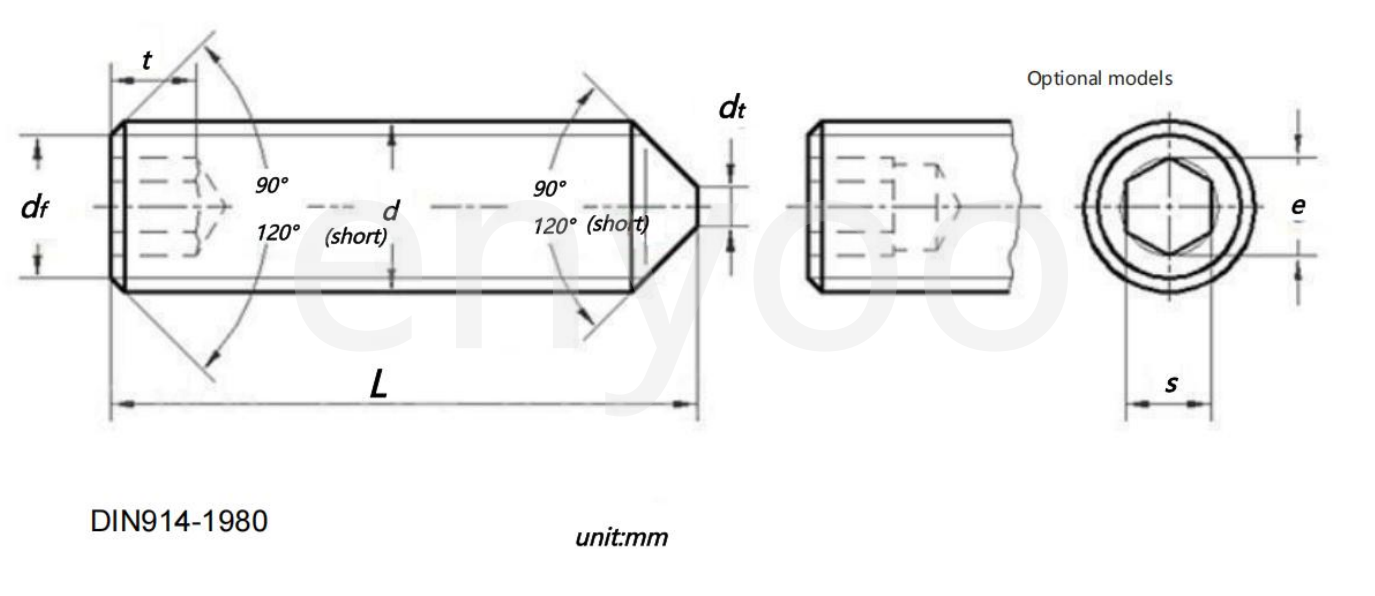

The top of the hexagonal cone-end set screw is conical, headless, and has a hexagonal groove. It can be used to connect parts or fix objects. The materials include carbon steel, alloy steel, stainless steel, copper, aluminum, etc. And the surface treatment can be natural or black Oxide , galvanized, etc. The tip of the DIN914 screw is tapered, and the tapered tip facilitates precise insertion into the reserved concave hole to provide good stopping, fixing, and positioning effects. Studies have shown that the hexagonal tapered end set screw can provide excellent wear resistance, and can perfectly fit the contact surface and maintain good fixation. Therefore, its durability is better than that of the hexagonal flat end and concave end. The set screw is fine. Hexagon socket cone-end set screws can be used in various mechanical equipment, automobile industry, electronic products, engineering construction and other fields. They not only have good torque transmission effect and tightening strength, but also have strong adaptability and wide application value.

The Specification Form of DIN914 is as bellow

| DIN914 | M | ||||||||||||

| D | 1.4 | 1.6 | 1.8 | 2 | 2.5 | 3 | 4 | 5 | 6 | ||||

| P | Pitch | 0.3 | 0.35 | 0.35 | 0.4 | 0.45 | 0.5 | 0.7 | 0.8 | 1 | |||

| dt | max | – | – | – | – | – | – | – | – | 1.5 | |||

| min | – | – | – | – | – | – | – | – | 0.9 | ||||

| e | min | 0.803 | 0.803 | 0.803 | 1.003 | 1.427 | 1.73 | 2.3 | 2.87 | 3.44 | |||

| s | Nominal Size | 0.7 | 0.7 | 0.7 | 0.9 | 1.3 | 1.5 | 2 | 2.5 | 3 | |||

| max | 0.724 | 0.724 | 0.724 | 0.902 | 1.295 | 1.545 | 2.045 | 2.56 | 3.08 | ||||

| min | 0.711 | 0.711 | 0.711 | 0.889 | 1.27 | 1.52 | 2.02 | 2.52 | 3.02 | ||||

| t | min | short | 0.6 | 0.7 | 0.8 | 0.8 | 1.2 | 1.2 | 1.5 | 2 | 2 | ||

| long | 1.4 | 1.5 | 1.6 | 1.7 | 2 | 2 | 2.5 | 3 | 3.5 | ||||

| L0 ② | Nominal Size | 2 | 2.5 | 2.5 | 2.5 | 3 | 3 | 4 | 5 | 6 | |||

| DIN914 | M | ||||||||||||

| D | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 | ||||

| P | Pitch | 1.25 | 1.5 | 1.75 | 2 | 2 | 2.5 | 2.5 | 2.5 | 3 | |||

| dt | max | 2 | 2.5 | 3 | 4 | 4 | 5 | 5 | 6 | 6 | |||

| min | 1.4 | 1.9 | 2.4 | 3.25 | 3.25 | 4.25 | 4.25 | 5.25 | 5.25 | ||||

| e | min | 4.58 | 5.72 | 6.86 | 6.86 | 9.15 | 11.43 | 11.43 | 13.72 | 13.72 | |||

| s | Nominal Size | 4 | 5 | 6 | 6 | 8 | 10 | 10 | 12 | 12 | |||

| max | 4.095 | 5.095 | 6.095 | 6.095 | 8.115 | 10.115 | 10.115 | 12.142 | 12.142 | ||||

| min | 4.02 | 5.02 | 6.02 | 6.02 | 8.025 | 10.025 | 10.025 | 12.032 | 12.032 | ||||

| t | min | short | 3 | 4 | 4.5 | 5.6 | 6.4 | 7.2 | 8 | 9 | 10 | ||

| long | 5 | 6 | 8 | 9 | 10 | 11 | 12 | 13.5 | 15 | ||||

| L0 ② | Nominal Size | 8 | 10 | 12 | 12 | 16 | 18 | 18 | 25 | 25 | |||

①df ≈ Minor thread diameter

②When L ≤ L0, it is a short screw; When L>L0, it is a long screw.

Product standard of this physical picture: DIN914

Spec:M4-0.7*4 Strength Class:A2-70 Material:SS304 Surface treatment:Plain

We are a professional Fastener manufacturer with a history of more than 20 years. Due to the large variety of screws, if you have other categories of standard parts and non-standard parts inquiries, please email us directly or contact us online. Looking forward to your contact.

Reviews

There are no reviews yet.