Fastener spring washers act as springs, absorb shock, and reduce friction between workpieces, allowing the machine to last longer. Spring washers are widely used in load-bearing and non-load-bearing structures of general mechanical products. They are characterized by low cost and easy installation. They are suitable for parts with frequent assembly and disassembly. They are widely used in automobile manufacturing, electronic equipment, instrumentation and other fields. A spring washer is installed under the nut to prevent the nut from loosening.

The commonly used materials for spring washers are 65MN spring steel or 70# carbon steel, 3Cr13, stainless steel materials SUS304 or SUS316 and phosphor bronze materials are also available. Specifications include Φ2-Φ100

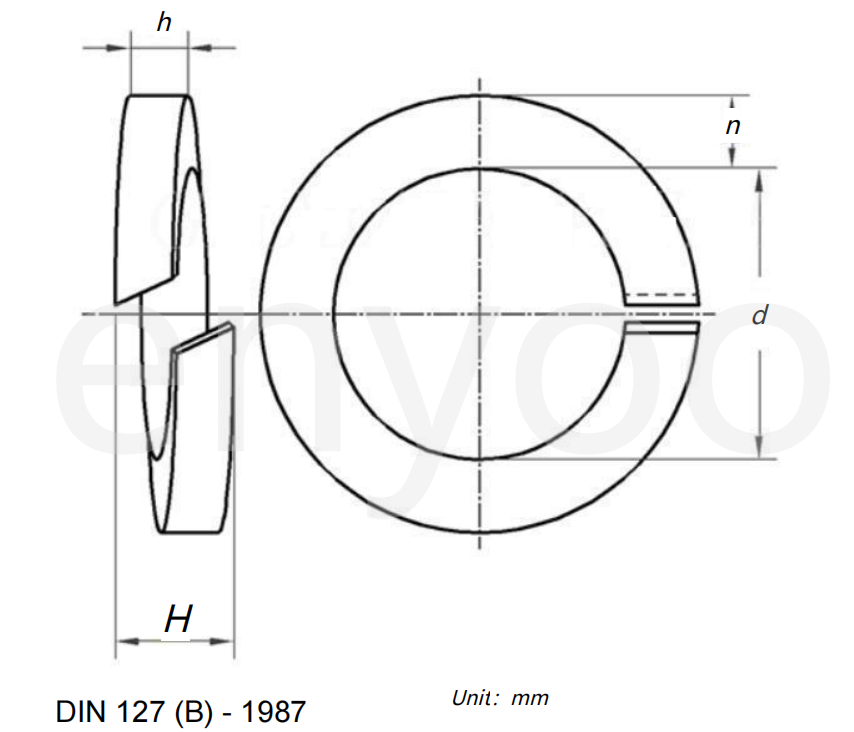

The Specification Form of DIN127B Single CoilSpring Lock Washer For Assembly is as bellow

| DIN127B | Φ | |||||||||||||

| Nominal Diameter | 2 | 2.2 | 2.5 | 3 | 3.5 | 4 | 5 | 6 | 7 | 8 | 10 | 12 | ||

| d | min | 2.1 | 2.3 | 2.6 | 3.1 | 3.6 | 4.1 | 5.1 | 6.1 | 7.1 | 8.1 | 10.2 | 12.2 | |

| max | 2.4 | 2.6 | 2.9 | 3.4 | 3.9 | 4.4 | 5.4 | 6.5 | 7.5 | 8.5 | 10.7 | 12.7 | ||

| n | Nominal Size | 0.9 | 1 | 1 | 1.3 | 1.3 | 1.5 | 1.8 | 2.5 | 2.5 | 3 | 3.5 | 4 | |

| max | 1 | 1.1 | 1.1 | 1.4 | 1.4 | 1.6 | 1.9 | 2.65 | 2.65 | 3.15 | 3.7 | 4.2 | ||

| min | 0.8 | 0.9 | 0.9 | 1.2 | 1.2 | 1.4 | 1.7 | 2.35 | 2.35 | 2.85 | 3.3 | 3.8 | ||

| h | Nominal Size | 0.5 | 0.6 | 0.6 | 0.8 | 0.8 | 0.9 | 1.2 | 1.6 | 1.6 | 2 | 2.2 | 2.5 | |

| max | 0.6 | 0.7 | 0.7 | 0.9 | 0.9 | 1 | 1.3 | 1.7 | 1.7 | 2.1 | 2.35 | 2.65 | ||

| min | 0.4 | 0.5 | 0.5 | 0.7 | 0.7 | 0.8 | 1.1 | 1.5 | 1.5 | 1.9 | 2.05 | 2.35 | ||

| H | min | 1 | 1.2 | 1.2 | 1.6 | 1.6 | 1.8 | 2.4 | 3.2 | 3.2 | 4 | 4.4 | 5 | |

| max | 1.2 | 1.4 | 1.4 | 1.9 | 1.9 | 2.1 | 2.8 | 3.8 | 3.8 | 4.7 | 5.2 | 5.9 | ||

| per 1000 units ≈ kg | 0.033 | 0.05 | 0.053 | 0.11 | 0.12 | 0.18 | 0.36 | 0.83 | 0.93 | 1.6 | 2.53 | 3.82 | ||

| DIN127B | Φ | |||||||||||||

| Nominal Diameter | 14 | 16 | 18 | 20 | 22 | 24 | 27 | 30 | 36 | 39 | 42 | 45 | ||

| d | min | 14.2 | 16.2 | 18.2 | 20.2 | 22.5 | 24.5 | 27.5 | 30.5 | 36.5 | 39.5 | 42.5 | 45.5 | |

| max | 14.7 | 17 | 19 | 21.2 | 23.5 | 25.5 | 28.5 | 31.7 | 37.7 | 40.7 | 43.7 | 46.7 | ||

| n | Nominal Size | 4.5 | 5 | 5 | 6 | 6 | 7 | 7 | 8 | 10 | 10 | 12 | 12 | |

| max | 4.7 | 5.2 | 5.2 | 6.2 | 6.2 | 7.25 | 7.25 | 8.25 | 10.25 | 10.25 | 12.25 | 12.25 | ||

| min | 4.3 | 4.8 | 4.8 | 5.8 | 5.8 | 6.75 | 6.75 | 7.75 | 9.75 | 9.75 | 11.75 | 11.75 | ||

| h | Nominal Size | 3 | 3.5 | 3.5 | 4 | 4 | 5 | 5 | 6 | 6 | 6 | 7 | 7 | |

| max | 3.15 | 3.7 | 3.7 | 4.2 | 4.2 | 5.2 | 5.2 | 6.2 | 6.2 | 6.2 | 7.25 | 7.25 | ||

| min | 2.85 | 3.3 | 3.3 | 3.8 | 3.8 | 4.8 | 4.8 | 5.8 | 5.8 | 5.8 | 6.75 | 6.75 | ||

| H | min | 6 | 7 | 7 | 8 | 8 | 10 | 10 | 12 | 12 | 12 | 14 | 14 | |

| max | 7.1 | 8.3 | 8.3 | 9.4 | 9.4 | 11.8 | 11.8 | 14.2 | 14.2 | 14.2 | 16.5 | 16.5 | ||

| per 1000 units ≈ kg | 6.01 | 8.91 | 9.73 | 15.2 | 16.5 | 26.2 | 28.7 | 44.3 | 67.3 | 71.7 | 111 | 117 | ||

| DIN127B | Φ | |||||||||||

| Nominal Diameter | 48 | 52 | 56 | 60 | 64 | 68 | 72 | 80 | 90 | 100 | ||

| d | min | 49 | 53 | 57 | 61 | 65 | 69 | 73 | 81 | 91 | 101 | |

| max | 50.5 | 54.5 | 58.5 | 62.5 | 66.5 | 70.5 | 74.5 | 82.5 | 92.5 | 102.5 | ||

| n | Nominal Size | 12 | 14 | 14 | 14 | 14 | 14 | 14 | 14 | 14 | 14 | |

| max | 12.25 | 14.25 | 14.25 | 14.25 | 14.25 | 14.25 | 14.25 | 14.25 | 14.25 | 14.25 | ||

| min | 11.75 | 13.75 | 13.75 | 13.75 | 13.75 | 13.75 | 13.75 | 13.75 | 13.75 | 13.75 | ||

| h | Nominal Size | 7 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | |

| max | 7.25 | 8.25 | 8.25 | 8.25 | 8.25 | 8.25 | 8.25 | 8.25 | 8.25 | 8.25 | ||

| min | 6.75 | 7.75 | 7.75 | 7.75 | 7.75 | 7.75 | 7.75 | 7.75 | 7.75 | 7.75 | ||

| H | min | 14 | 16 | 16 | 16 | 16 | 16 | 16 | 16 | 16 | 16 | |

| max | 16.5 | 18.9 | 18.9 | 18.9 | 18.9 | 18.9 | 18.9 | 18.9 | 18.9 | 18.9 | ||

| per 1000 units ≈ kg | 123 | 182 | 193 | 203 | 218 | 228 | 240 | 262 | 290 | 318 | ||

①Material:

FST = spring steel according to DIN 267 part 26

DIN 267-26: Spring washer should be made using spring steel (FST) manufacturing compliant DIN 17 221 or DIN 17 222; Spring washer hardness HV430-530

Product standard of this physical picture: DIN127B

Spec:φ2-φ6 Material:SS304 Surface treatment:Plain

We are a professional Fastener manufacturer with a history of more than 20 years. Due to the large variety of screws, if you have other categories of standard parts and non-standard parts inquiries, please email us directly or contact us online. Looking forward to your contact

Reviews

There are no reviews yet.