The head of the external hexagonal bolt is hexagonal and the shaft is threaded. Generally, the shorter one is full thread and the longer one is half thread. The materials of external hexagonal bolts generally include carbon steel, stainless steel, brass, nylon plastic, etc. Hexagonal bolts made of carbon steel generally include grade 4.8, grade 8.8, grade 10.9, and grade 12.9. Grades 8.8 and above are all made of alloy steel. The hardness and tensile properties of alloy steel are much better. These are also called high-strength bolts.

Commonly the stainless steel hexagonal bolts include SUS201 / SUS316 / SUS304. The tensile strength grades are divided into 45, 50, 60, 70 and 80. Due to the material characteristics of stainless steel bolts, their anti-corrosion performance will be better and their appearance will be bright. Hexagonal bolts are widely used indoors and outdoors.

Stainless steel (SUS) hex bolts are used in a variety of industrial applications, including:

Construction: Used in the erection, repair, and maintenance of buildings, bridges, and road infrastructure

Oil and gas: Used in oil and gas applications

They are also mostly used indoors in mechanical equipment, medical equipment, electronic instruments, etc.

In the fields of electronic instruments, medical instruments, stainless steel hexagonal bolts are generally chosen because the surface color of stainless steel is brighter and has better anti-corrosion properties, so it can maintain its appearance for a long time.

DIN standard is a set of guidelines for products, processes, and services developed by the German Institute for Standardization (DIN). DIN standards are used in many industries to ensure the quality of products and materials.

Many DIN standards have been the basis for ISO standards. When DIN standards are changed to ISO standards, minor adjustments are often made.

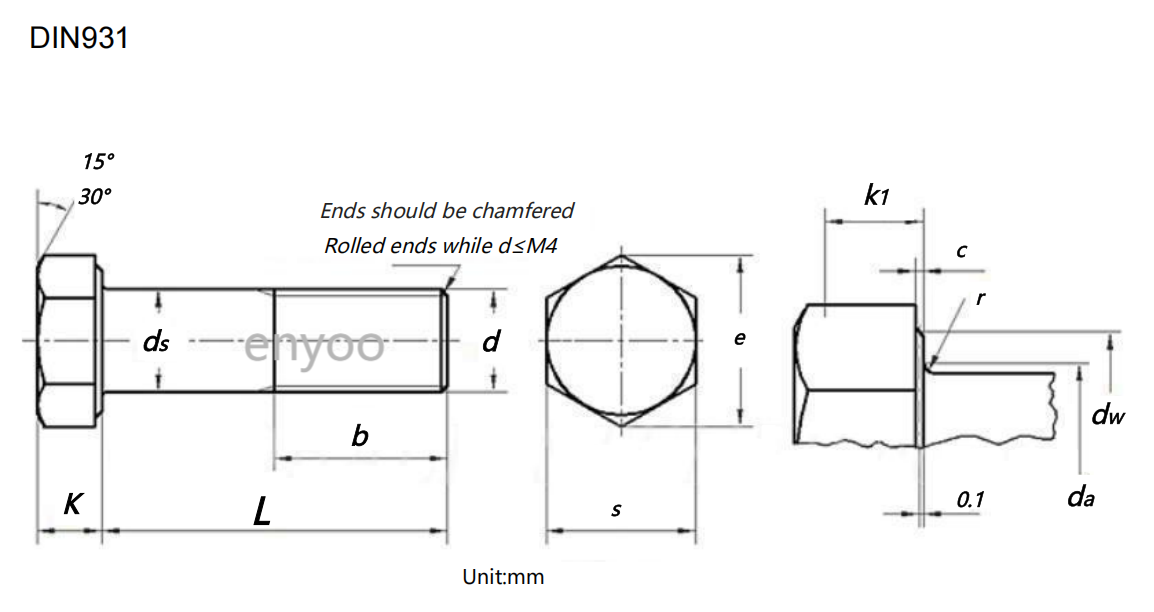

DIN 931 is a German standard that specifies the dimensions and properties of partially threaded hex head bolts. They are often used in construction and engineering applications.The bolt has an unthreaded shank, which means only part of the bolt is threaded.The standard defines the bolt’s tensile strength, hardness, and surface finish.

DIN931 size parameters are as follows:

| Thread Size | M | ||||||||||||||

| d | 1.6 | 2 | 2.5 | 3 | 3.5 | 4 | 5 | 6 | 7 | 8 | 10 | 12 | |||

| P | Thread Pitch | 0.35 | 0.4 | 0.45 | 0.5 | 0.6 | 0.7 | 0.8 | 1 | 1 | 1.25 | 1.5 | 1.75 | ||

| b | Ref. | L≤125 | 9 | 10 | 11 | 12 | 13 | 14 | 16 | 18 | 20 | 22 | 26 | 30 | |

| 125<L≤200 | – | – | – | – | – | – | 22 | 24 | 26 | 28 | 32 | 36 | |||

| L>200 | – | – | – | – | – | – | – | – | – | – | 45 | 49 | |||

| c | min | 0.1 | 0.1 | 0.1 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | ||

| max | 0.25 | 0.25 | 0.25 | 0.4 | 0.4 | 0.4 | 0.5 | 0.5 | 0.5 | 0.6 | 0.6 | 0.6 | |||

| da | max | 2 | 2.6 | 3.1 | 3.6 | 4.1 | 4.7 | 5.7 | 6.8 | 7.8 | 9.2 | 11.2 | 13.7 | ||

| ds | max=nominal size | 1.6 | 2 | 2.5 | 3 | 3.5 | 4 | 5 | 6 | 7 | 8 | 10 | 12 | ||

| min | Grade A | 1.46 | 1.86 | 2.36 | 2.86 | 3.32 | 3.82 | 4.82 | 5.82 | 6.78 | 7.78 | 9.78 | 11.73 | ||

| Grade B | – | – | – | – | – | – | – | – | – | – | – | – | |||

| dw | min | Grade A | 2.4 | 3.2 | 4.1 | 4.6 | 5.1 | 5.9 | 6.9 | 8.9 | 9.8 | 11.6 | 15.6 | 17.4 | |

| Grade B | – | – | – | – | – | – | – | – | – | – | – | – | |||

| e | min | Grade A | 3.41 | 4.32 | 5.45 | 6.01 | 6.58 | 7.66 | 8.79 | 11.05 | 12.12 | 14.38 | 18.9 | 21.1 | |

| Grade B | – | – | – | – | – | – | – | – | – | – | – | – | |||

| k | Nominal Size | 1.1 | 1.4 | 1.7 | 2 | 2.4 | 2.8 | 3.5 | 4 | 4.8 | 5.3 | 6.4 | 7.5 | ||

| Grade A | min | 0.98 | 1.28 | 1.58 | 1.88 | 2.28 | 2.68 | 3.35 | 3.85 | 4.65 | 5.15 | 6.22 | 7.32 | ||

| max | 1.22 | 1.52 | 1.82 | 2.12 | 2.52 | 2.92 | 3.65 | 4.15 | 4.95 | 5.45 | 6.58 | 7.68 | |||

| Grade B | min | – | – | – | – | – | – | – | – | – | – | – | – | ||

| max | – | – | – | – | – | – | – | – | – | – | – | – | |||

| k1 | min | 0.7 | 0.9 | 1.1 | 1.3 | 1.6 | 1.9 | 2.28 | 2.63 | 3.19 | 3.54 | 4.28 | 5.05 | ||

| r | min | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.2 | 0.2 | 0.25 | 0.25 | 0.4 | 0.4 | 0.6 | ||

| s | max=nominal size | 3.2 | 4 | 5 | 5.5 | 6 | 7 | 8 | 10 | 11 | 13 | 17 | 19 | ||

| min | Grade A | 3.02 | 3.82 | 4.82 | 5.32 | 5.82 | 6.78 | 7.78 | 9.78 | 10.73 | 12.73 | 16.73 | 18.67 | ||

| Grade B | – | – | – | – | – | – | – | – | – | – | – | – | |||

| Thread Size | M | |||||||||||||

| d | 14 | 16 | 18 | 20 | 22 | 24 | 27 | 30 | 33 | 36 | 39 | |||

| P | Thread Pitch | 2 | 2 | 2.5 | 2.5 | 2.5 | 3 | 3 | 3.5 | 3.5 | 4 | 4 | ||

| b | Ref. | L≤125 | 34 | 38 | 42 | 46 | 50 | 54 | 60 | 66 | 72 | 78 | 84 | |

| 125<L≤200 | 40 | 44 | 48 | 52 | 56 | 60 | 66 | 72 | 78 | 84 | 90 | |||

| L>200 | 53 | 57 | 61 | 65 | 69 | 73 | 79 | 85 | 91 | 97 | 103 | |||

| c | min | 0.15 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.3 | ||

| max | 0.6 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 1 | |||

| da | max | 15.7 | 17.7 | 20.2 | 22.4 | 24.4 | 26.4 | 30.4 | 33.4 | 36.4 | 39.4 | 42.4 | ||

| ds | max=nominal size | 14 | 16 | 18 | 20 | 22 | 24 | 27 | 30 | 33 | 36 | 39 | ||

| min | Grade A | 13.73 | 15.73 | 17.73 | 19.67 | 21.67 | 23.67 | – | – | – | – | – | ||

| Grade B | – | 15.57 | 17.57 | 19.48 | 21.48 | 23.48 | 26.48 | 29.48 | 32.38 | 35.38 | 38.38 | |||

| dw | min | Grade A | 20.5 | 22.5 | 25.3 | 28.2 | 30 | 33.6 | – | – | – | – | – | |

| Grade B | – | 22 | 24.8 | 27.7 | 29.5 | 33.2 | 38 | 42.7 | 46.6 | 51.1 | 55.9 | |||

| e | min | Grade A | 24.49 | 26.75 | 30.14 | 33.53 | 35.72 | 39.98 | – | – | – | – | – | |

| Grade B | – | 26.17 | 29.56 | 32.95 | 35.03 | 39.55 | 45.2 | 50.85 | 55.37 | 60.79 | 66.44 | |||

| k | Nominal Size | 8.8 | 10 | 11.5 | 12.5 | 14 | 15 | 17 | 18.7 | 21 | 22.5 | 25 | ||

| Grade A | min | 8.62 | 9.82 | 11.28 | 12.28 | 13.78 | 14.78 | – | – | – | – | – | ||

| max | 8.98 | 10.18 | 11.72 | 12.72 | 14.22 | 15.22 | – | – | – | – | – | |||

| Grade B | min | – | 9.71 | 11.15 | 12.15 | 13.65 | 14.65 | 16.65 | 18.28 | 20.58 | 22.08 | 24.58 | ||

| max | – | 10.29 | 11.85 | 12.85 | 14.35 | 15.35 | 17.35 | 19.12 | 21.42 | 22.92 | 25.42 | |||

| k1 | min | 5.96 | 6.8 | 7.8 | 8.5 | 9.6 | 10.3 | 11.7 | 12.8 | 14.4 | 15.5 | 17.2 | ||

| r | min | 0.6 | 0.6 | 0.6 | 0.8 | 0.8 | 0.8 | 1 | 1 | 1 | 1 | 1 | ||

| s | max=nominal size | 22 | 24 | 27 | 30 | 32 | 36 | 41 | 46 | 50 | 55 | 60 | ||

| min | Grade A | 21.67 | 23.67 | 26.67 | 29.67 | 31.61 | 35.38 | – | – | – | – | – | ||

| Grade B | – | 23.16 | 26.16 | 29.16 | 31 | 35 | 40 | 45 | 49 | 53.8 | 58.8 | |||

We are a professional Fastener manufacturer with a history of more than 20 years. Due to the large variety of screws, if you have other categories of standard parts and non-standard parts inquiries, please email us directly or contact us online. Looking forward to your contact.

Reviews

There are no reviews yet.