The differences between

American hose clamp and German hose clamp

Throat hoops, also known as hose clamps,Hose hoops are mainly divided into British, American and German styles. Materials usually include stainless steel and iron.

Can be used to fasten pipes and ducts and hoses.

They can be used in a variety of applications, including

1.Securing water and gas pipes.

2.Fastening hoses in automotive cooling systems.

3.Fastening exhaust ducts

4.Holding large pipes

5.Clamping diesel and petrol pipes

Hose clamps can be roughly divided into American style, German style and European style. They all have good strength. Today we will focus on the differences between American style and German style:

We mainly explain from the following aspects:

Appearance size

First, the width of the steel strip is different.

American hose clamp: steel belt width is 12.7mm, small American belt width is 8mm.

German hose clamp: steel belt width is 12mm or 9mm.

Secondly, we compare the design features and applicable scenarios of American and German hose clamps.

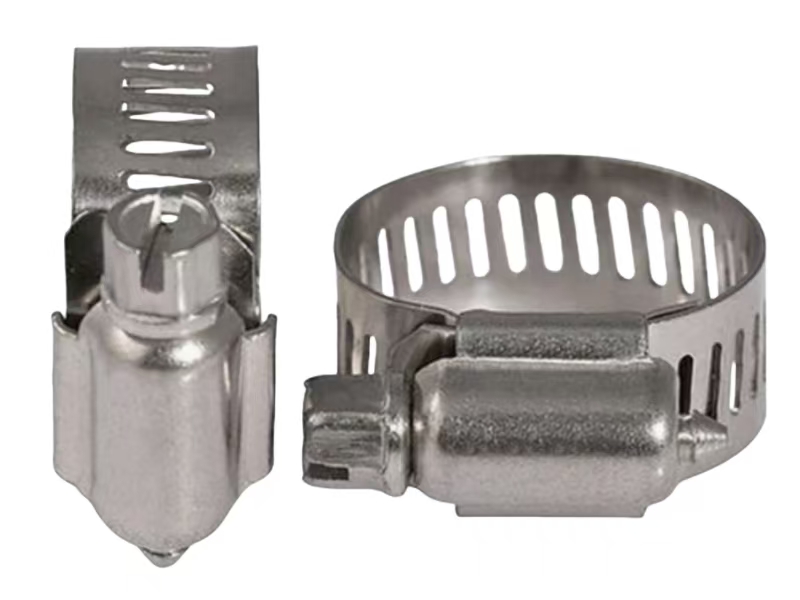

The design of the American throat clamp: the steel belt has holes in the thread, and the bite groove is a through hole type, the teeth of the screw are embedded in it, and the locking is more powerful and the bite is accurate.

The design of the German throat clamp: because the steel belt is different from the American type, it is not through-hole, but adopts a flanging design, which has great resistance to distortion and pressure, and can achieve a very tight tightening effect.

Furthermore, the application scenarios of American hose clamps are mainly used in transportation tools such as automobiles, bulldozers, cranes and ships.

The application scenarios of German hose clamps are widely used in vehicles, ships, chemical petroleum, medicine, agriculture and mining.

Finally, the disadvantages of the American hose clamp are: because the steel belt is perforated, it is easy to break when the tension is strong, and the tensile performance is not as good as the German hose clamp.

The advantages of the German hose clamp are: superior performance, low friction, wide range of use, and can meet high-demand connection needs.

From the characteristics of American and German hose clamps, we can infer the difference in load-bearing between them:

Load-bearing capacity: Since the steel belt of the American hose clamp is easy to break when the tension is strong, its load-bearing capacity is relatively weak.

Applicable scenarios: Mainly used in transportation vehicles such as automobiles, bulldozers, cranes and ships.

Load-bearing capacity: German hose clamp has very strong resistance to twisting and pressure, and can achieve a very tight tightening effect, so its load-bearing capacity is stronger.

Applicable scenarios: Widely used in vehicles, ships, chemical petroleum, medicine, agriculture, mining and other fields.

If “strong hose clamp” refers to a hose clamp with super strong load-bearing capacity, then it is closer to the characteristics of German hose clamp. German hose clamps are usually able to withstand higher loads due to their excellent resistance to twisting and pressure.

In order to ensure safety and correct selection of hose clamps, it is recommended to select the appropriate type of hose clamp according to the specific application scenario and load-bearing requirements. For example, German hose clamps should be selected in the chemical industry because they have better resistance to twisting and pressure.

The American and German clamp fastening dimensions are as follows:

| America Style | German Style | ||||

| SIZE (inch) | Size (mm) | Band’s width | Size (mm) | Band’s width | |

| mm | mm | ||||

| 3/8″ | 6-10mm | 8 | 8-12 | 9 | |

| 1/2″ | 6-13mm | 10-16 | |||

| 5/8″ | 6-16mm | 12-20 | |||

| 3/4″ | 11-20mm | 12-22 | |||

| 7/8″ | 13-23mm | 16-27 | |||

| 1″ | 16-25mm | 20-32 | |||

| 1-1/16″ | 14-27mm | 25-40 | |||

| 1-1/4″ | 18-32mm | 30-45 | |||

| 3/4″ | 11-20mm | 12.7 | 35-50 | ||

| 7/8″ | 13-23mm | 40-60 | |||

| 1-1/16″ | 14-27mm | 50-70 | |||

| 1-1/4″ | 18-32mm | 60-80 | |||

| 1-1/2″ | 21-38mm | 70-90 | |||

| 1-3/4″ | 21-44mm | 80-100 | |||

| 2″ | 27-51mm | 90-110 | |||

| 2-1/4″ | 33-57mm | 100-120 | |||

| 2-1/2″ | 40-63mm | 110-130 | |||

| 2-3/4″ | 46-70mm | 120-140 | |||

| 3″ | 52-76mm | 130-150 | |||

| 3-1/4″ | 59-82mm | 140-160 | |||

| 3-1/2″ | 65-89mm | 160-180 | |||

| 3-3/4″ | 72-95mm | 16-27 | 12 | ||

| 4″ | 78-101mm | 20-32 | |||

| 4-1/4″ | 84-108mm | 25-40 | |||

| 4-1/2″ | 91-114mm | 30-45 | |||

| 4-3/4″ | 95-120mm | 35-50 | |||

| 5″ | 105-127mm | 40-60 | |||

| 5-1/4″ | 110-134mm | 50-70 | |||

| 5-1/2″ | 118-140mm | 60-80 | |||

| 5-3/4″ | 125-146mm | 70-90 | |||

| 6″ | 130-152mm | 80-100 | |||

| 6 1/4″ | 133-159mm | 90-110 | |||

| 6-1/2″ | 143-165mm | 100-120 | |||

| 6 3/4″ | 146-171mm | 110-130 | |||

| 7″ | 155-178mm | 120-140 | |||

| PleaseInquire, If you have another dimensions. | 130-150 | ||||

| 140-160 | |||||

How to choose high-quality hose clamps ? Control from the following two points:

※High tightening force

The perfect meshing of the thread enables the clamp to produce a strong and reliable sealing pressure around the hose. High-quality clamps should produce uniform and strong tightening force around the hose or pipe. Only uniform and strong tightening force can ensure sealing. You can choose the required pressure according to the torque for practical application.

※No damage to the hose

The clamp with a smooth and solid inner wall of the band and the outward rolled edge can reduce damage to the hose, thereby reducing the risk of leakage. Choosing a clamp means choosing a clamp that can tightly clamp the hose.

How to choose a hose clamp supplier and buy high-quality hose clamps? That is to have a qualified test report, The main size tests include thickness, width, clamping range, head size, etc., especially thickness and width are very important.