Self-tapping screws can directly tap into softer materials, such as plastic, wood, thin metal plates, etc., and tap out threads by themselves without pre-drilling. This characteristic allows self-tapping screws to effectively fasten two or more workpieces together. Self-tapping screws have a special thread design, which is usually thicker and has a larger pitch. They can drill themselves into the material and form matching threads during the installation process. This design eliminates the need for pre-drilling or tapping during the installation process. The screws can be screwed directly into the material, which significantly improves the installation efficiency and is more suitable for connecting non-metallic or soft metal materials,such as wood, plastic,aluminum alloy, etc.

Self-tapping screws are used in a wide range of applications, including furniture, construction, electronics and automotive industries. In furniture production, self-tapping screws can be used to connect wooden boards, metal brackets, etc. In construction, self-tapping screws can be used to fix walls, floors, etc. In the electronics industry, self-tapping screws can be used to connect circuit boards, plastic shells, etc. In automobile manufacturing, self-tapping screws can be used to connect bodywork, doors, etc. These applications often require screws to fasten materials quickly and easily without requiring excessive preparation of the material.

Countersunk head self-tapping screws are a type of screws whose heads are not higher than the driven plane after tightening, which can keep the surface smooth and beautiful.

Cross recessed countersunk head self-tapping screws are mainly made of carbon steel and stainless steel. Iron-carbon alloys with a carbon content WC of less than 2% ,belong to eutectoid steel and hypereutectoid steel. They have high strength and hardness and good wear resistance. In addition to carbon, carbon steel generally also contains small amounts of silicon, manganese, sulfur, Phosphorus, according to its use, carbon steel can be divided into three categories: carbon structural steel, carbon tool steel and free-cutting structural steel. According to the carbon content, carbon steel can be divided into low carbon steel (WC ≤ 0.25%), medium carbon steel (WC0.25%-0.6%) and high carbon steel (WC>0.6%). Stainless steel standard parts are relatively soft and have good ductility. For example, the hardness of stainless steel standard parts is SUS316. Compared with the hardness of iron standard parts, they are both softer than iron standard parts of level 8.8.

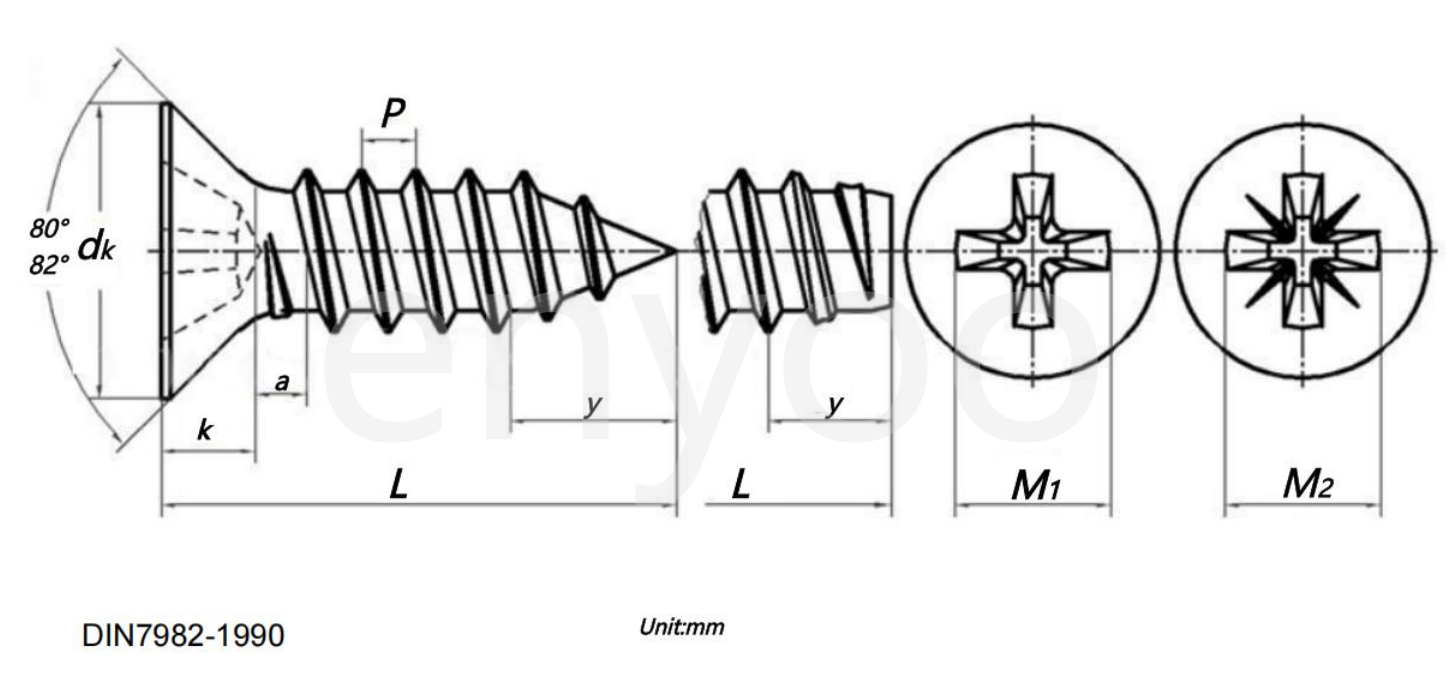

The Specification Form of DIN7982 is as bellow

| DIN7982 | ST | |||||||||||

| D | 2.2 | 2.9 | 3.5 | 3.9 | 4.2 | 4.8 | 5.5 | 6.3 | ||||

| P | Pitch | 0.8 | 1.1 | 1.3 | 1.3 | 1.4 | 1.6 | 1.8 | 1.8 | |||

| a | max | 0.8 | 1.1 | 1.3 | 1.3 | 1.4 | 1.6 | 1.8 | 1.8 | |||

| dk | max=nominal size | 4.3 | 5.5 | 6.8 | 7.5 | 8.1 | 9.5 | 10.8 | 12.4 | |||

| min | 4 | 5.2 | 6.44 | 7.14 | 7.74 | 9.14 | 10.37 | 11.97 | ||||

| k | ≈ | 1.3 | 1.7 | 2.1 | 2.3 | 2.5 | 3 | 3.4 | 3.8 | |||

| y | max | Type C | 2 | 2.6 | 3.2 | 3.5 | 3.7 | 4.3 | 5 | 6 | ||

| Type F | 1.6 | 2.1 | 2.5 | 2.7 | 2.8 | 3.2 | 3.6 | 3.6 | ||||

| Socket No. | 1 | 1 | 2 | 2 | 2 | 2 | 3 | 3 | ||||

| M1 | ≈ | 2.5 | 3 | 4.2 | 4.6 | 4.7 | 5.1 | 6.8 | 7.1 | |||

| M2 | ≈ | 2.4 | 2.8 | 4 | 4.2 | 4.4 | 5 | 6.3 | 7 | |||

Product standard of this physical picture: DIN7982

Spec:ST2.2*13 Material:1022 Surfacetreatment:Heat treatment,Black Zinc plated

We are a professional Fastener manufacturer with a history of more than 20 years. Due to the large variety of screws, if you have other categories of standard parts and non-standard parts inquiries, please email us directly or contact us online. Looking forward to your contact.

Reviews

There are no reviews yet.